Our Projects

Advanced Thermal Solutions for Industrial Applications

Discover a comprehensive range of thermal and heat transfer solutions, engineered for high performance and durability across various industrial applications, including power generation, chemical processing, and HVAC systems.

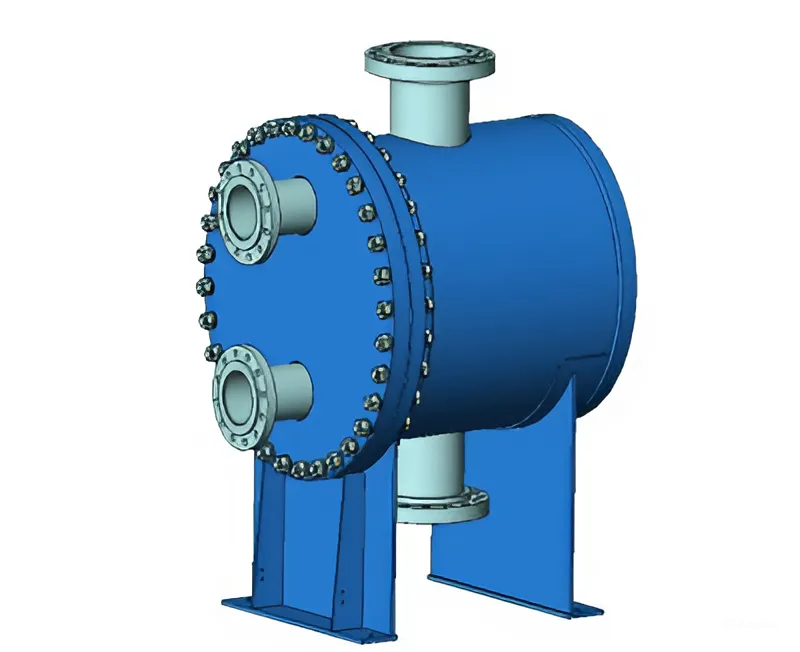

Shell and Tube Heat Exchangers

At HeatKal Technologies, our Shell and Tube Heat Exchangers are engineered for robust performance and high efficiency. These versatile exchangers are ideal for handling fluids at different temperatures and pressures across a wide range of industries, including power plants, chemical processing, and HVAC systems. Designed and manufactured to meet stringent international standards like TEMA and ASME, they ensure long-term reliability and optimal heat transfer performance.

SUPERDISC - Shell and Plate Heat Exchangers

Our Shell and Plate Heat Exchangers provide the perfect solution for applications requiring compact designs with high thermal efficiency. They combine the benefits of both shell and tube and plate heat exchangers, making them ideal for processes that need efficient heat transfer in limited space. We customize each unit to suit specific customer requirements, ensuring superior performance in industries such as chemical processing, oil and gas, and HVAC.

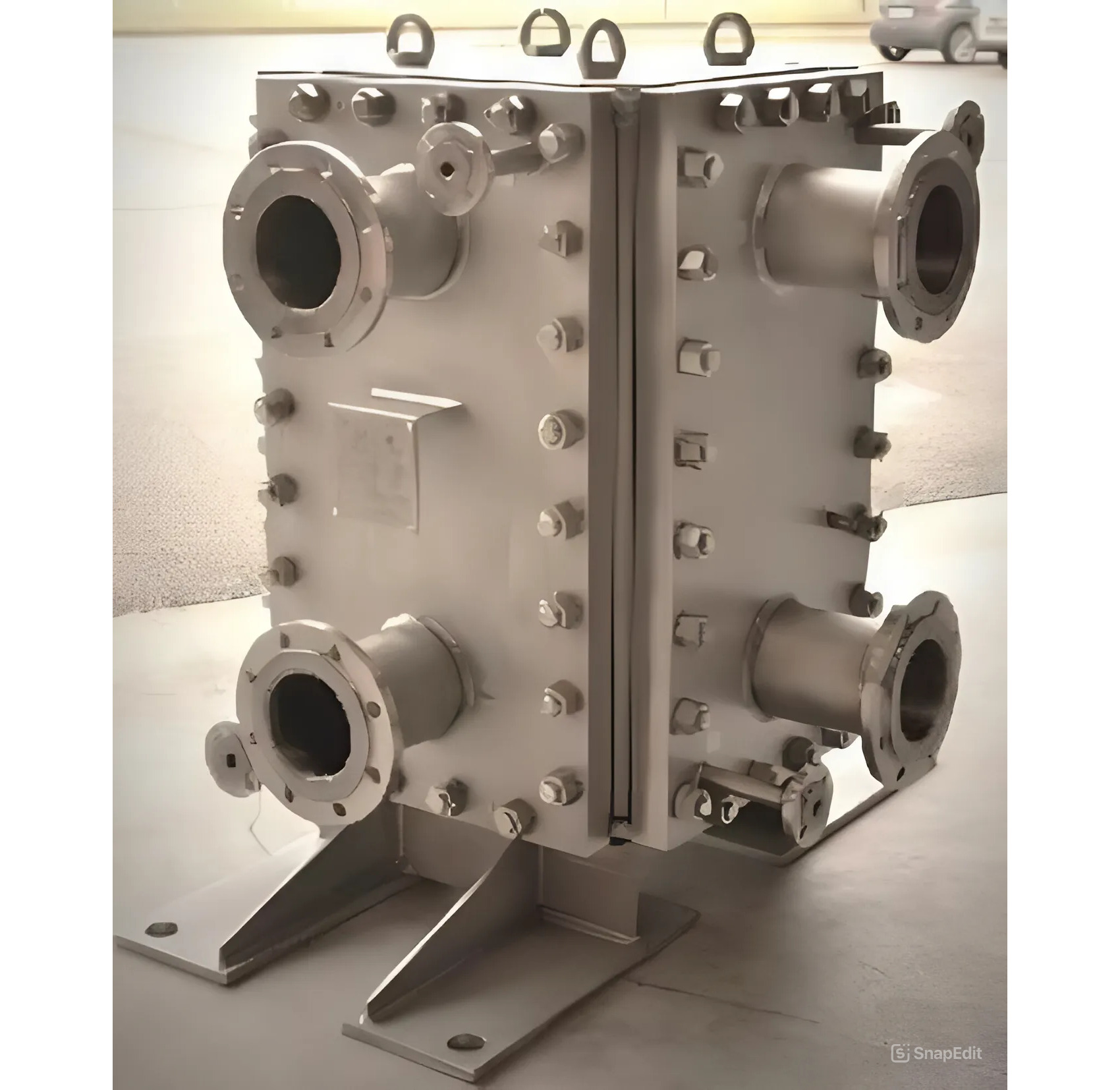

HK Bloc - Block Heat Exchangers

Block Heat Exchangers at HeatKal Technologies offer unparalleled reliability and compactness, making them perfect for operations involving extreme temperatures and pressures. These exchangers are particularly well-suited for corrosive and high-viscosity fluids, ensuring effective and efficient heat transfer. With our cutting-edge manufacturing techniques and materials like stainless steel and titanium, we promise durability and longevity in all critical industrial applications.

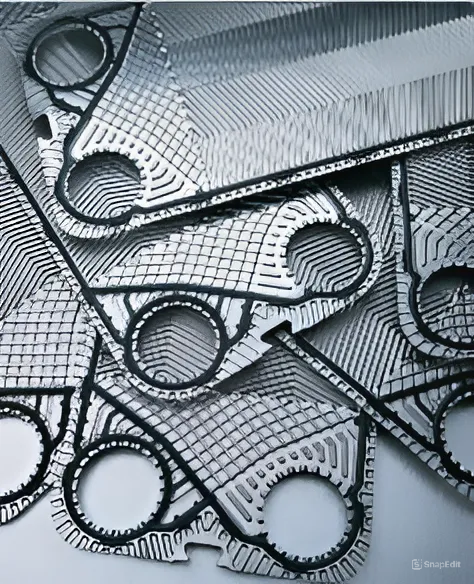

Plate Heat Exchangers and Spares

HeatKal Technologies specializes in high-efficiency Plate Heat Exchangers (PHEs), designed to provide compact, low-cost heat transfer solutions. Our PHEs are tailored for a range of industries, from food processing to chemical and pharmaceutical sectors. Additionally, we offer a comprehensive range of PHE spares, including gaskets and plates, ensuring seamless operations and minimal downtime for your systems.

Box Type Heat Exchangers

Our Box Type Heat Exchangers are engineered for compactness and high efficiency, especially for applications where space is at a premium. These exchangers are known for their Tough construction, low maintenance requirements, and flexibility in various industrial applications. Built to last, they are ideal for use in Solvent Recover plant, water treatment plants, HVAC systems, and energy recovery systems.

Falling / Rising Film Evaporator

The Falling and Rising Film Evaporators designed by HeatKal Technologies offer efficient concentration of liquids, optimizing heat transfer for energy-intensive processes. Suitable for industries like food processing, chemical manufacturing, and pharmaceuticals, our evaporators are built for high-performance, low energy consumption, and easy maintenance, making them an ideal solution for reducing operational costs.

Steam Coil Air Pre-Heater (SCAPH)

Our Steam Coil Air Pre-Heaters (SCAPH) are designed to maximize energy efficiency in boilers and other industrial processes. These heat exchangers recover waste heat from flue gases to preheat combustion air, thus improving overall system efficiency and reducing fuel consumption. With customizable designs, we cater to various industries such as power generation, refineries, and paper manufacturing.

Fin-Fan Coolers / Air Cooled Condenser

Our Fin-Fan Coolers and Air-Cooled Condensers are designed to provide reliable, energy-efficient cooling solutions in various industrial applications. These exchangers are especially suited for environments where water is scarce or costly. By leveraging advanced fin technology, they deliver exceptional heat transfer rates, making them the perfect solution for petrochemical, power generation, and gas processing industries.

Heat Exchanger Servicing

HeatKal Technologies offers comprehensive Heat Exchanger Servicing, ensuring optimal performance and longevity for all types of heat exchangers. Our skilled technicians provide cleaning, re-tubing, re-gasketing, and full refurbishment services, extending the operational life of your equipment and minimizing downtime. We adhere to global standards to guarantee the best results, no matter the make or model of your heat exchanger.

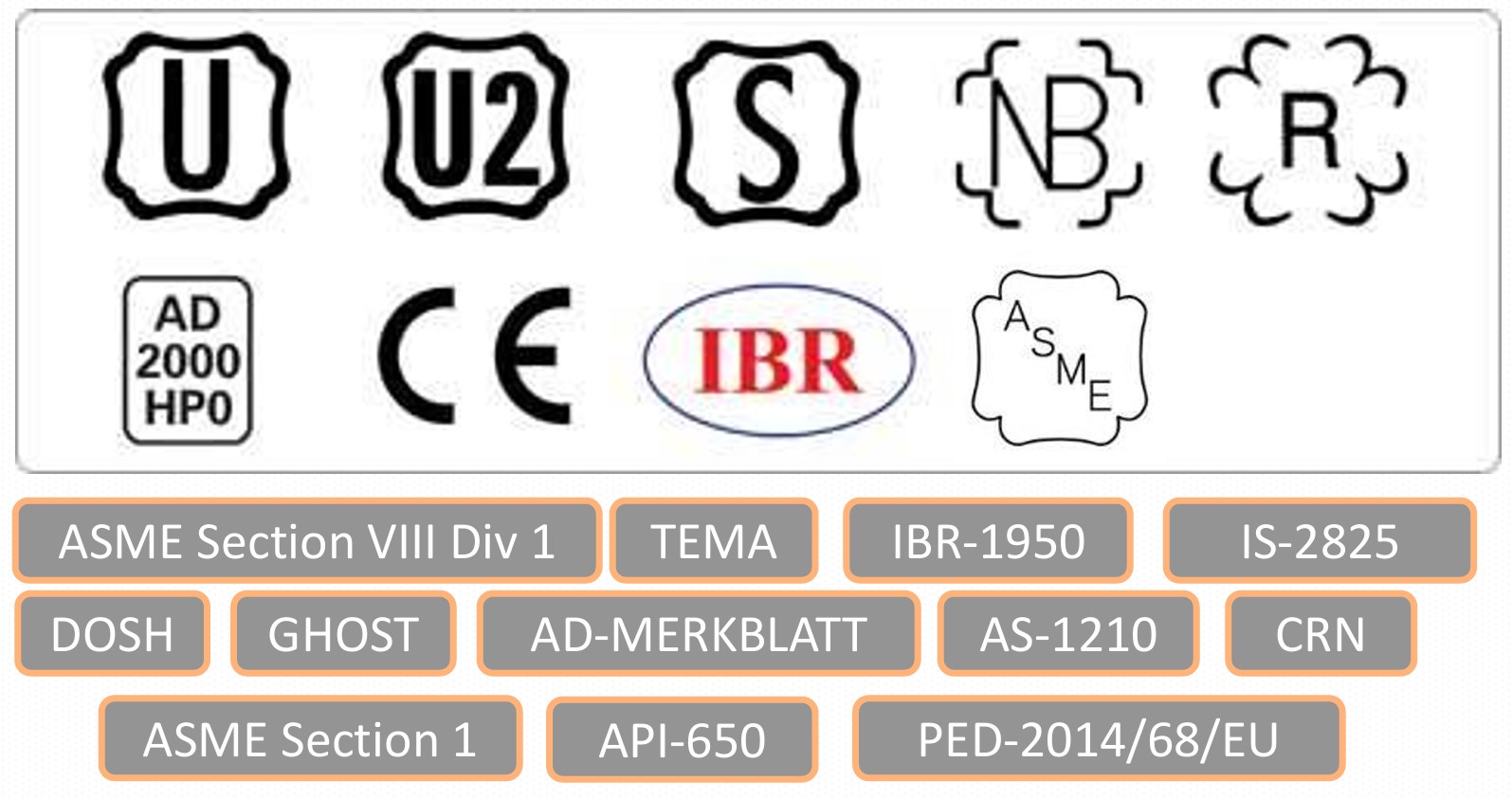

Manufacturing Practices

At HeatKal Technologies, we follow the highest global standards in manufacturing. Our products are built under rigorous certifications such as CE Marking, IBR, ASME (U, U2, S), NB, R Stamp, TEMA, CRN, DOSH, and GOST. These certifications ensure that each heat exchanger is manufactured for durability, safety, and performance in compliance with international codes and standards, giving you peace of mind and unmatched reliability.